Solid wedge gate valve.

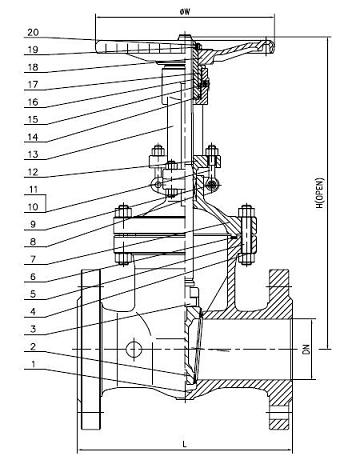

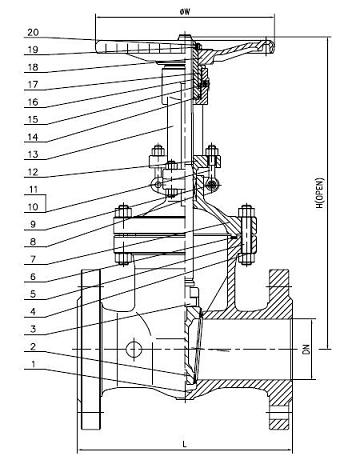

Rising stem gate valve diagram.

Types of stem movement.

Steam water and general service applications.

Gate valves are classified as either rising stem or nonrising stem valves.

Designed for quick shutoff in.

When it comes to gate valves grainger s got your back.

Female threaded ends allow for ease of installation.

Rising stem or os y type outside stem and screw type non rising stem type.

The external valve stem threads prevent contamination from flow media.

For the nonrising stem gate valve the stem is threaded on the lower end into the gate.

Pvc gate valves fipt.

The gate faces can be parallel but are most commonly wedge shaped in order to be able to apply pressure on the sealing surface.

Stem nut for open stem gate valve is on its cover.

A gate valve also known as a sluice valve is a valve that opens by lifting a barrier gate out of the path of the fluid gate valves require very little space along the pipe axis and hardly restrict the flow of fluid when the gate is fully opened.

Shop a large range of rising stem valve at msc industrial supply.

Orbit rising stem ball valve.

Compared with other valves gate valves have a wider range of combined applications for pressure service fluid design pressure and temperature.

Msc industrial supply is here to support all your metalworking and maintenance repair needs with over 1 million products in stock and ready to ship today.

Solid wedge is the most common widely used disk type because of its simplicity and strength.

The largest stocking distributor of orbit valves.

According to the screw position of the stem the gate valve can be divided into rising stem gate valves and non rising stem gate valve nrs.

The cameron orbit rising stem ball valve is ideal for applications when zero leakage and frequent operation are demanded.

The solid wedge integral seats and bi directional service make the gate valve a good choice for a broad range of services.

Non rising 212 rising 165 brand apollo 10 asahi 8 grainger approved 49.

Rising stem gate valves are used when shutoff is required and a quick visual indicator of open closed position is needed.

A valve with a solid wedge may be installed in any position and it is suitable for almost all fluids.